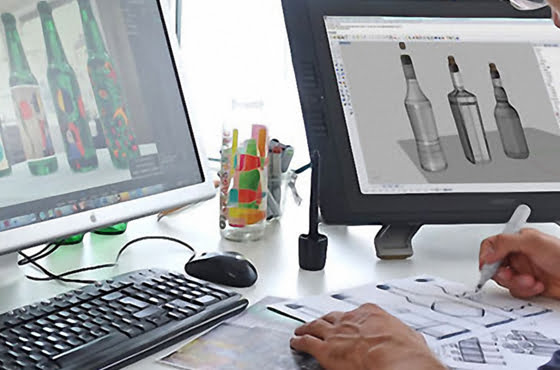

1. Understand your custom glass bottle design

We have more than 20 years of design and customization experience. Whether it is a sketch, technical drawing or 3D drawing, we can accurately understand your design and provide suggestions, reduce costs, communicate quickly and efficiently, and reduce customer time costs.

2. Custom Glass Bottle Drawing

We will quickly and accurately technical drawings and 3D drawings according to your design intent, and display all the data and three-dimensional models in detail to confirm that it is what you like.

3. Making Custom Glass Molds

Molds are the key to realizing your ideas in glass. Maidao Glass offer a full-set of production moulds, and depending on the size of the bank, good for around 500,000 pieces. In the event that a mass production moulds expires, either during or after its design-life, Maidao Glass will replace it free of charge.

4. Glass Bottle Samples Setup

Samples setup before mass production is the best test method. In this process, customers will obtain 5-10 physical samples for filling testing, lid testing and commercial packaging to get a real feeling, but also the smallest Ways to correct the design.

5. Custom Glass Bottle Manufacturing and Packaging

The Glass Bottle manufacturing begins by feeding the treated raw material into the furnace. When the mixture melts, it is put into the molds. The “blow and blow” or “press and blow” forming method is used to form bottles.